Programming

- Python, C++, C, Embedded C

- MATLAB / Simulink

- Bash scripting

Name: Mohammad Ibrahim Memon

Role: Robotics Engineer | Autonomous Systems Specialist | Embedded Developer

Education: M.Sc Autonomous Systems @ HBRS, B.Tech Mechatronics

- 🤖 Robotics Engineer focused on system integration, real-time embedded systems, and

hardware-software co-design.

- 🧠 MSc Autonomous Systems student at H-BRS (Bonn-Rhein-Sieg University of Applied

Sciences).

- 🔬 Keen interest in simulation, control systems, and autonomy.

- 💡 Constantly learning and exploring how to make robots smarter, faster, and more reliable.

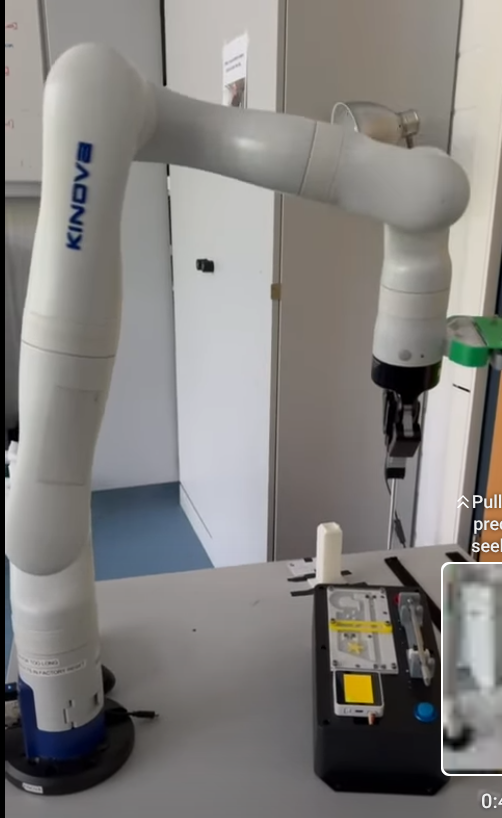

- Robothon 2025 (Kinova Gen3)

- ILP Fault Detection (R&D)

- Garrulus Seeding Mechanism (PCB Design)

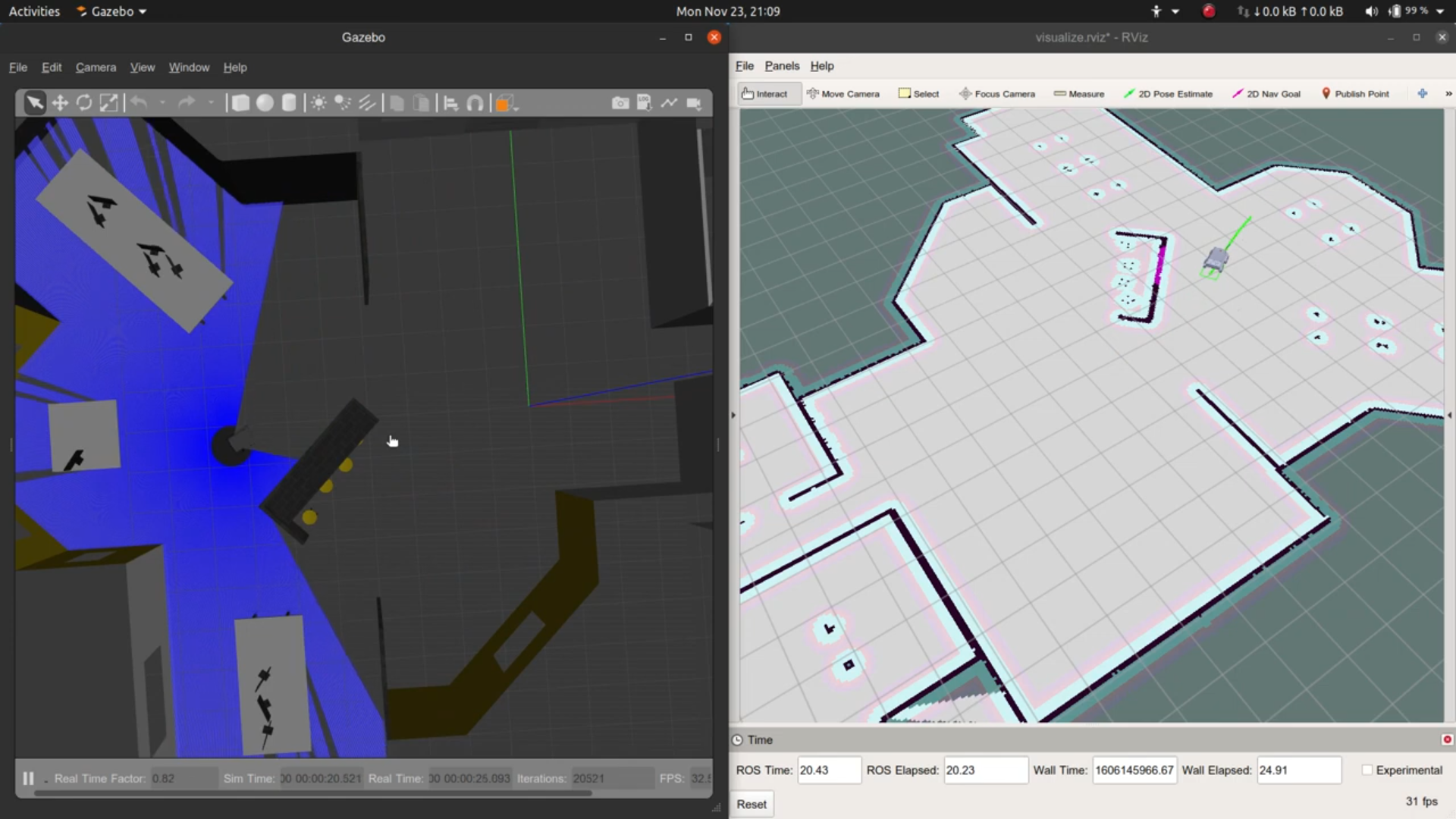

- Autonomous Mobile Robot (LiDAR, ROS)

- Underwater ROV System

> Sum up my profile: [TRUE]

Achieved a Top 5 ranking in an international competition by automating complex manipulation tasks.

Robothon

Kinova Gen3

ROS

Python

C++

MoveIt

OpenCV

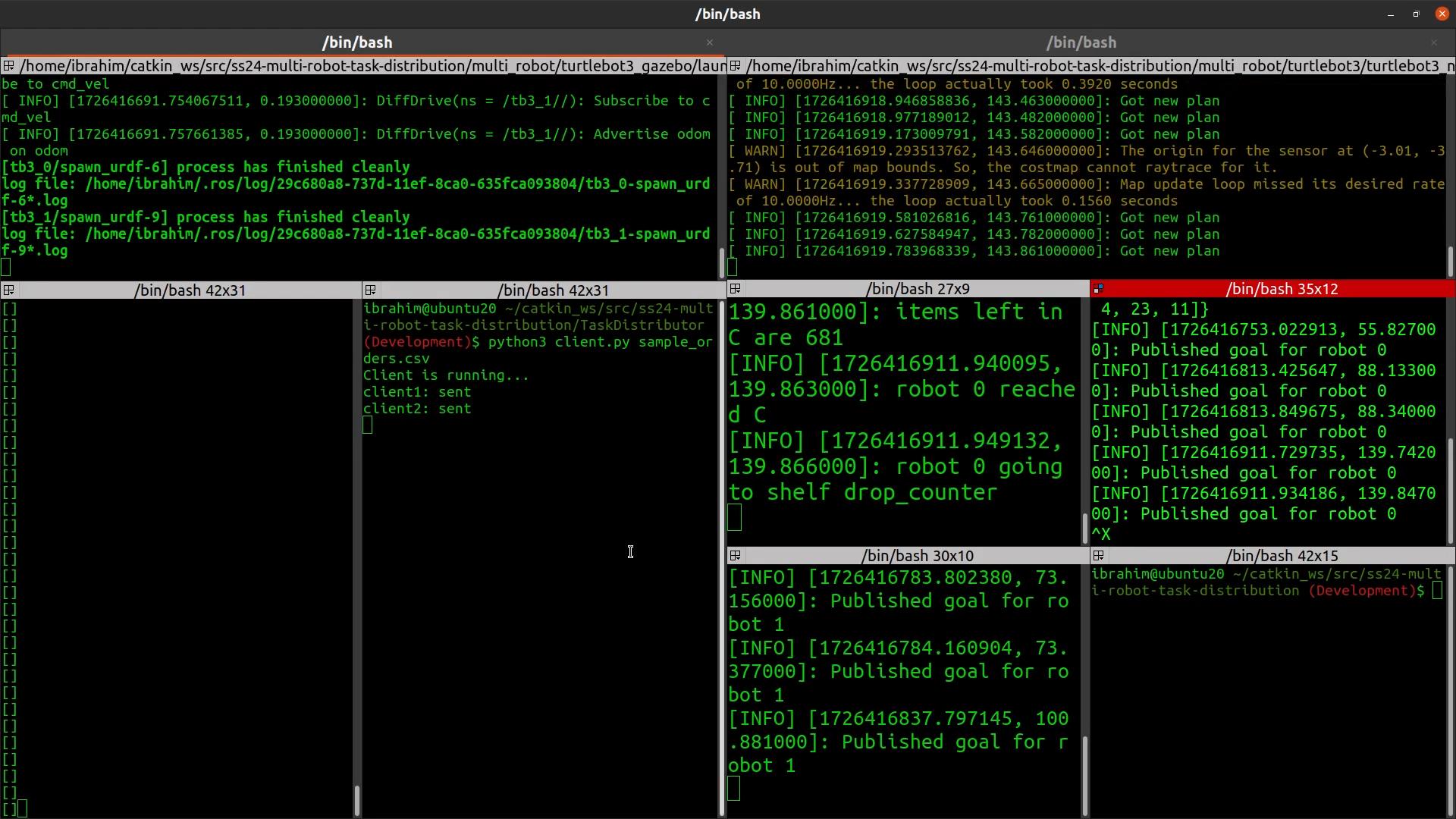

Interpretable fault detection framework for mobile robots using Inductive Logic Programming (ILP).

ROS

Python

Prolog

ILP

Fault Detection

Symbolic task allocation framework generating interpretable rules for multi-robot systems.

ROS2

Python

Prolog

Multi-Robot Systems

Explainable AI

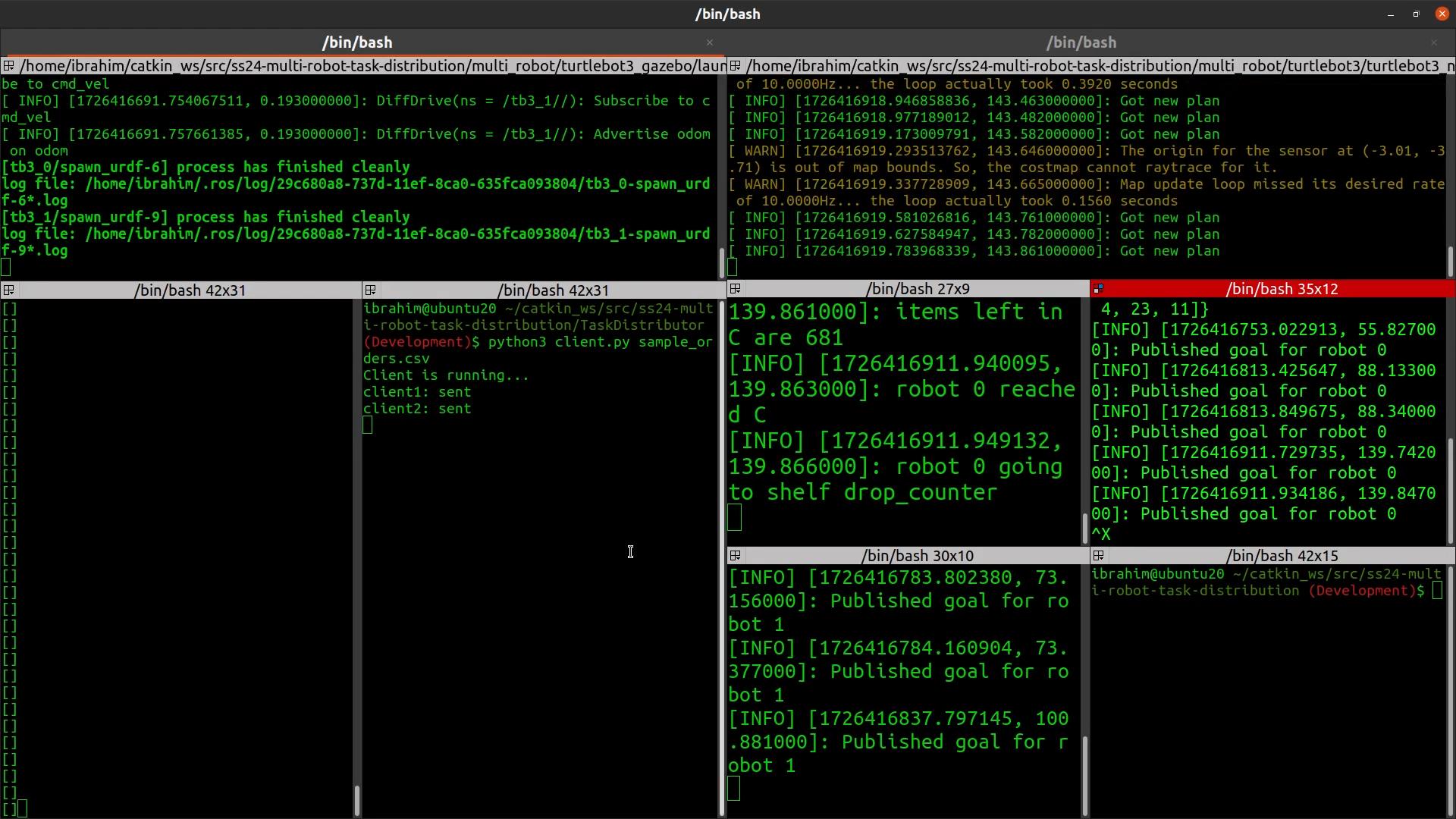

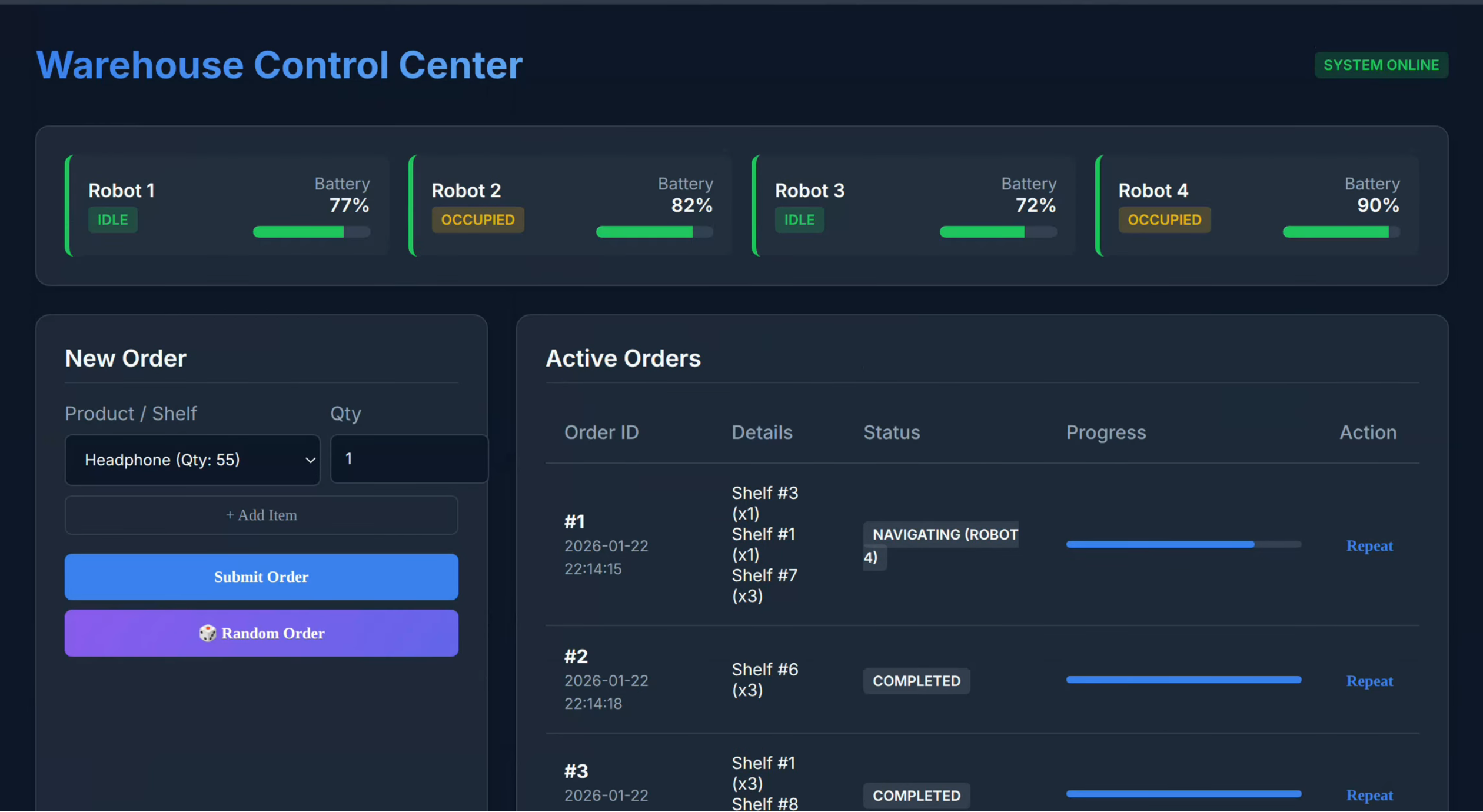

Scalable, decentralized multi-robot task allocation framework for dynamic environments.

Multi-Robot Systems

Task Allocation

ROS2

Gazebo

CI/CD

Designed and developed an AMR capable of navigation in unknown spaces.

AMRROSSLAMMotion Planning

LidarElectronics Design

> Doing what I love...